Industrial Circular Blades: Enhancing Precision in Manufacturing

The realm of industrial manufacturing is driven by precision and efficiency. A significant aspect of achieving these objectives lies in the tools utilized—specifically, industrial circular blades. These cutting-edge tools are pivotal in various sectors, from woodworking to metal fabrication. Understanding their features, benefits, and proper maintenance can dramatically enhance productivity and operational efficacy.

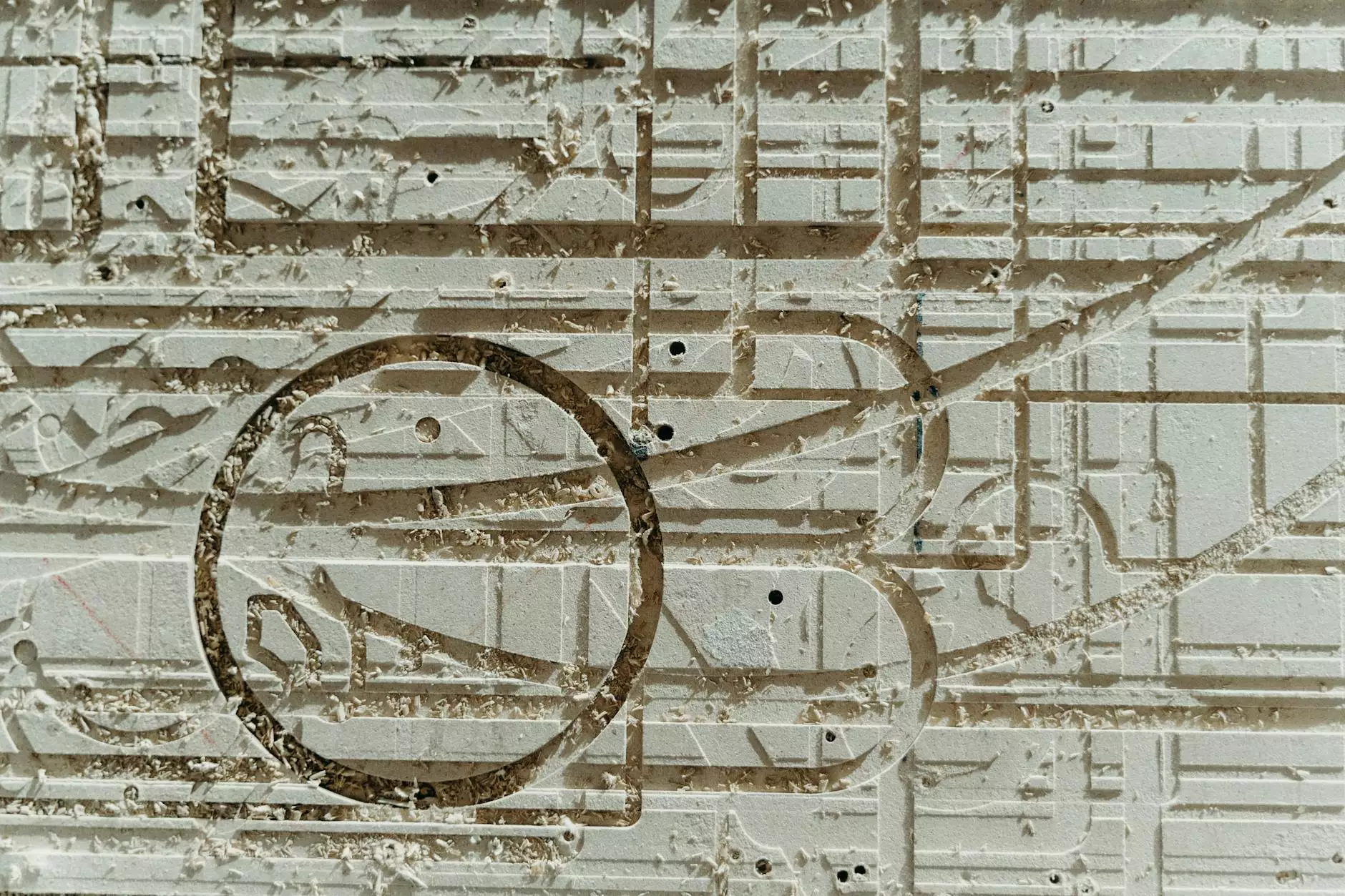

Understanding Industrial Circular Blades

Industrial circular blades are circular cutting devices often constructed from high-quality materials such as high-speed steel, carbide, and other durable composites. These blades are designed to perform precision cutting across a myriad of materials, including wood, plastic, metal, and various composites. Notably, the efficiency of these blades often dictates the performance of the machinery they are integrated with, influencing aspects like speed, accuracy, and the quality of the finished product.

Composition and Construction

The construction of industrial circular blades is tailored for resilience and longevity. Key components include:

- Material: Most industrial blades are made of high-speed steel or tungsten carbide to endure high temperatures and stress.

- Coating: Many are coated with titanium or similar materials to enhance performance by reducing friction and wear.

- Tooth Design: The configuration of the teeth (size, shape, and spacing) is critical for efficiency dependent on the material being cut.

Applications of Industrial Circular Blades

Industrial circular blades are integral to varied industries, performing a multitude of cutting tasks. Here are a few key applications:

1. Woodworking

In woodworking, these blades are essential for making precision cuts in lumber and composite materials. Different tooth configurations can yield smooth finishes or aggressive cuts based on project requirements.

2. Metal Fabrication

For metal cutting, specialized industrial circular blades are employed to ensure clean cuts in steel sheets and other metals. Their durability is crucial as they frequently encounter high-performance demands.

3. Textile Industry

In textiles, these blades are used for cutting fabric layers, offering high accuracy which is vital for garment production and design.

Benefits of Using Industrial Circular Blades

Utilizing industrial circular blades provides various advantages that constitute a significant return on investment. Some of these benefits include:

- Precision Cutting: The circular design allows for smooth and accurate cuts, aiding in achieving tight tolerances in manufacturing.

- Increased Efficiency: With the right blade, production times can be decreased significantly, enhancing overall workflow.

- Versatility: These blades can be adapted for numerous materials, making them invaluable across different manufacturing processes.

- Cost-Efficiency: Their longevity and ability to maintain sharpness reduce the frequency of replacements, lowering operational costs.

- Improved Safety: Because of their design and construction, industrial circular blades can often reduce the risk of accidents compared to traditional cutting methods.

Choosing the Right Industrial Circular Blade

Selecting the appropriate industrial circular blade is crucial for optimal performance. Here are key considerations:

Material Compatibility

It’s essential to choose a blade compatible with the material being cut. For instance, blades designed for metal will differ significantly from those intended for wood.

Blade Diameter

The diameter of the blade affects the cutting capacity and depth. Larger blades tend to cut deeper and are better for larger projects, while smaller blades may provide more control for intricate designs.

Tooth Configuration

Different tooth types serve various purposes. Fine-toothed blades are ideal for smooth cuts, while coarse-toothed blades are designed for faster, rougher cuts.

Professional Services for Industrial Circular Blades

To maintain optimum performance of industrial circular blades, professional services are essential. This includes:

Knife Sharpening Services

Regular sharpening can extend the life of blades significantly. Professional sharpening services use sophisticated techniques that ensure blades are restored to their original sharpness, preserving the quality of cuts.

Blade Repair and Maintenance

Beyond sharpening, maintaining blades entails regular inspections and repairs to manage wear and expected lifespan. Professionals can recommend when a blade should be replaced, which is vital for operational safety.

Investment in Quality Industrial Circular Blades

Investing in high-quality industrial circular blades from reputable manufacturers ensures that you receive products that deliver reliability and high-performance standards. Companies like szblade.com provide a range of options tailored to specific manufacturing needs, making them a suitable source for dependable tools.

Factors to Consider When Investing

- Manufacturer Reputation

- Customer Support

- Warranty and Guarantee

- Industry Reviews and Testimonials

Safety Considerations When Using Industrial Circular Blades

Ensuring safety in operations that utilize industrial circular blades cannot be overstated. Here are key safety tips:

1. Proper Training

Employees must receive comprehensive training on how to operate machinery that utilizes these blades effectively and safely.

2. Protective Equipment

Use of Personal Protective Equipment (PPE) such as gloves, goggles, and containment measures can minimize risks while handling blades.

3. Regular Inspections

Consistency in inspecting both the blades and machinery they are fitted to can prevent accidents and enhance overall workplace safety.

Future Trends in Industrial Circular Blade Technology

As industries evolve, the technology surrounding industrial circular blades is advancing. Key trends include:

1. Smart Blades

Innovation towards smart technology includes blades that can alert operators when sharpening or replacement is necessary.

2. Eco-Friendly Materials

With sustainability becoming increasingly important, manufacturers are exploring biodegradable materials that retain performance while being environmentally friendly.

3. Automated Cutting Processes

Automation and robotics are seeping into manufacturing workflows, driving the demand for blades that can integrate seamlessly with automated cutting systems.

Conclusion

In summation, industrial circular blades are indispensable tools in modern manufacturing. Their effectiveness in cutting various materials with precision makes them invaluable across numerous industries. By investing in quality blades, utilizing professional services for maintenance and sharpening, and adhering to safety protocols, businesses can maximize efficiency and enhance output.

For businesses seeking reliable solutions, szblade.com stands out as a provider of premium industrial circular blades, ready to meet diverse manufacturing needs.