Etching Stainless Steel 304: Techniques, Benefits, and Applications

Etching stainless steel 304 is a sophisticated technique widely utilized in the metal fabrication industry. Renowned for its superior corrosion resistance and strength, stainless steel 304 presents an ideal canvas for various etching processes used to enhance aesthetics, functionality, and branding. This article explores the intricacies of etching stainless steel 304, including the methods, benefits, and applications across diverse industries, specifically focusing on how these practices can elevate your business operations and product offerings.

Understanding Stainless Steel 304

Stainless steel 304 is one of the most commonly used grades of stainless steel. Its versatility makes it suitable for a broad range of applications, from kitchenware to industrial components. Here are a few reasons why stainless steel 304 is so popular:

- Corrosion Resistance: 304 stainless steel exhibits excellent resistance to a variety of corrosive environments.

- Durability: Known for its high tensile strength, stainless steel 304 can withstand heavy usage and extreme conditions.

- Formability: This grade is easy to fabricate and can be shaped into intricate designs, making it perfect for varied applications.

- Hygienic Properties: Its non-porous surface is easy to clean and maintain, making it ideal for the food industry.

- Aesthetic Appeal: Stainless steel 304 has a natural luster that enhances the visual appeal of products.

The Etching Process

Etching is a type of surface treatment used to create designs on stainless steel surfaces. The etching process involves the removal of material using chemical or physical means. When it comes to etching stainless steel 304, the following methods are commonly employed:

Chemical Etching

Chemical etching, also known as photochemical etching, involves using corrosive chemicals to dissolve the stainless steel in specific areas, creating detailed designs. Here’s how the process works:

- Design Preparation: The first step is to prepare the design artwork, which is typically created using CAD software.

- Masking: The design is printed onto a protective film that is applied to the stainless steel surface.

- Etching: The stainless steel is submerged in a corrosive solution that reacts with the exposed metal, etching the design.

- Clearing: After the desired depth is achieved, the part is rinsed and the protective film is removed.

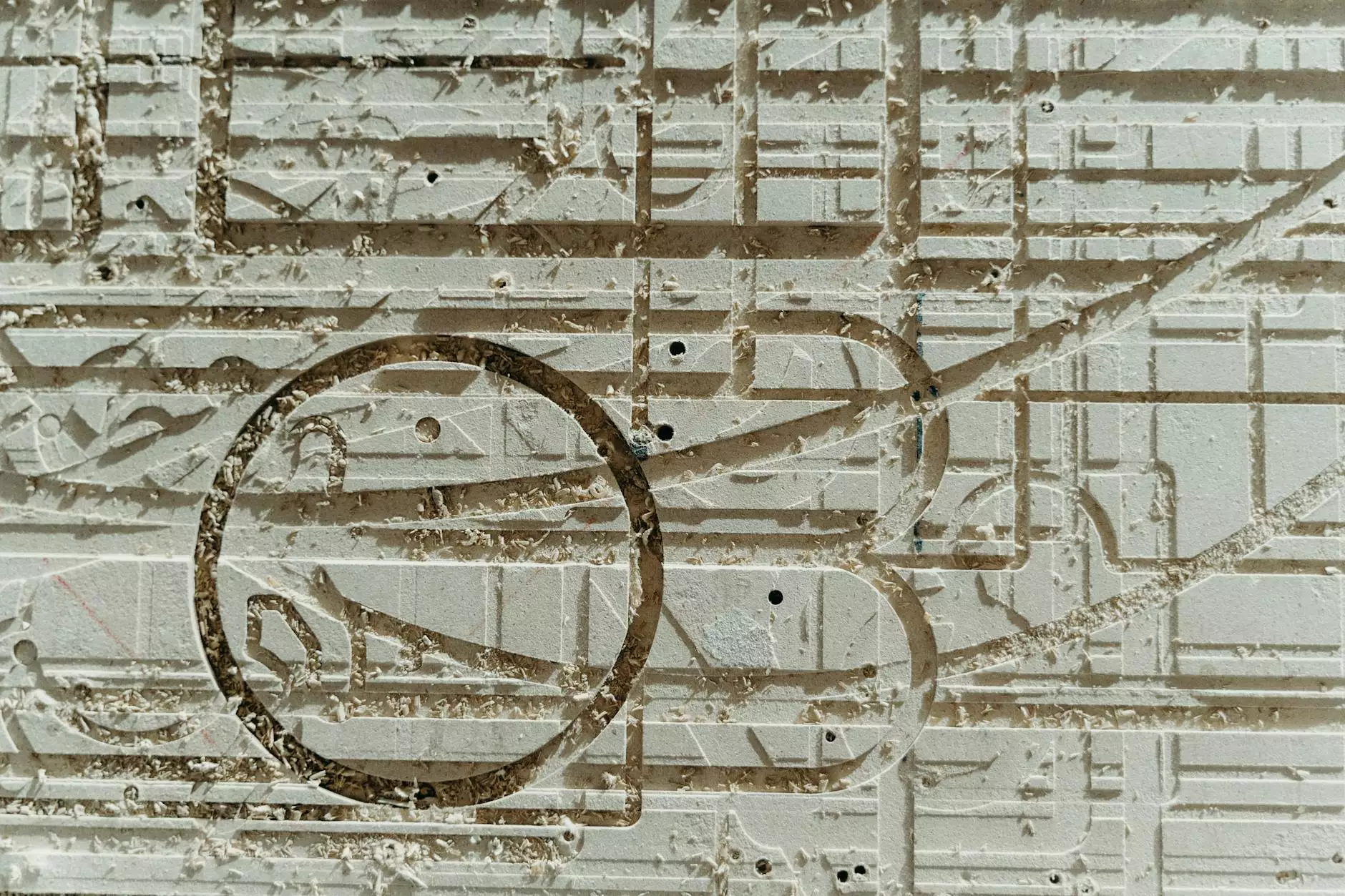

Laser Etching

Another popular method for etching stainless steel 304 is through laser technology, providing precise control over the etching depth and detail. The process includes:

- Design Creation: Similar to chemical etching, the design is created digitally.

- Laser Setup: A laser etching machine is configured to the appropriate settings for stainless steel 304.

- Etching Process: The laser beam is directed at the surface, vaporizing the material to create the design.

- Finishing Touches: The component may undergo additional cleaning or polishing to achieve the desired finish.

Benefits of Etching Stainless Steel 304

Etching stainless steel 304 offers a multitude of benefits that can significantly enhance both the functionality and appearance of the material. Here are some key advantages:

1. Enhanced Aesthetic Appeal

Etching allows businesses to add intricate designs and patterns to their stainless steel components. This aesthetic enhancement can elevate a product's marketability, making it stand out in competitive markets.

2. Improved Branding

Utilizing etching for logos or brand names on stainless steel products can increase brand visibility and recognition. Customers often associate quality with visually appealing designs.

3. Increased Functionality

Etching can create functional surfaces, such as non-slip patterns or textured finishes, which improve the performance of the product in its intended application. For example, etching can create a rough surface on items like countertops to enhance grip.

4. Versatile Customization

The flexibility of etching processes means that custom designs can be produced with relative ease. This adaptability makes it ideal for businesses looking to create tailor-made solutions for their clients.

5. Cost-effectiveness

Etching stainless steel 304 is often a cost-effective method for producing high-quality designs compared to other forms of metalworking, helping businesses reduce their overall production costs while maintaining standards.

Applications of Etched Stainless Steel 304

The etching of stainless steel 304 finds practical applications across various industries, showcasing its adaptability and usefulness. Here are a few notable applications:

1. Architectural Elements

In architecture, etched stainless steel can be used for decorative panels, railings, and facade elements. The intricate designs not only add beauty but also durability, enhancing the overall aesthetic of buildings.

2. Kitchenware

In the culinary world, etched designs on kitchen tools, appliances, and countertop surfaces not only serve aesthetic purposes but can also offer texturing that aids in food preparation and safety.

3. Industrial Equipment

Industrial machines benefit from etching by incorporating safe grips, safety instructions, and other functional markings that ensure operational safety and efficiency.

4. Signage

Custom signage made from etched stainless steel offers durability and visibility in various environments, from corporate offices to outdoor spaces.

5. Artwork and Sculptures

Artists frequently utilize etching to create stunning sculptures and artwork that leverage the characteristics of stainless steel 304, producing eye-catching pieces that reflect light beautifully.

Conclusion

In conclusion, etching stainless steel 304 is more than just a decorative technique; it is a valuable process that enhances the functionality and aesthetic appeal of products across numerous industries. From the precision of laser etching to the chemical art of photochemical etching, businesses can leverage these techniques to create customized solutions that meet market demands.

For companies in the metal fabrication sector, understanding and applying the etching process can provide a competitive edge, allowing for innovation in product design and functionality. As stainless steel continues to be a staple in manufacturing, etching presents an opportunity to reinvigorate traditional materials into modern masterpieces.

Whether you're in construction, culinary arts, or artistic endeavors, investing in etched stainless steel can lead to enhanced product offerings and strengthened market presence. Embrace the possibilities of etching stainless steel 304 for your business today.

For more information on etching techniques and stainless steel solutions, visit goldecosteel.com.