The Incredible Impact of Tooling Molds in Metal Fabrication Industry

In the realm of Metal Fabricators, one essential element that stands out as a game-changer is tooling molds. These molds, while seemingly simple in design, hold immense power in shaping the way manufacturers operate and produce their products efficiently and effectively. Let's delve into the world of tooling molds and uncover their significant impact on the metal fabrication industry.

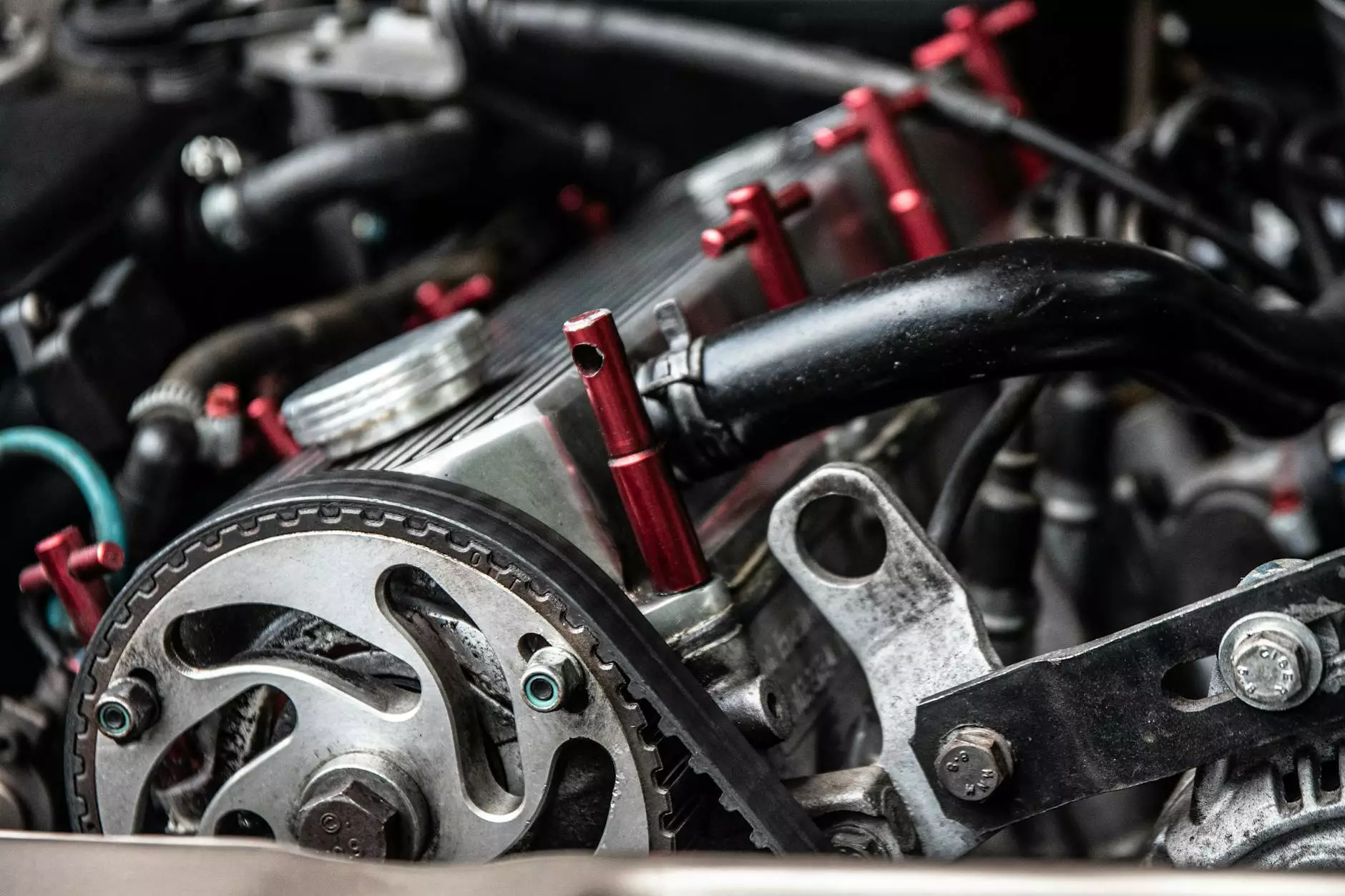

Understanding Tooling Molds

Tooling molds are meticulously crafted devices used by metal fabricators to create and shape various metal components. These molds serve as the foundation for producing intricate parts with precision and consistency. Through the use of tooling molds, manufacturers can streamline their production processes, minimize errors, and achieve uniformity in their final products.

The Evolution of Tooling Molds

Over the years, tooling molds have undergone significant advancements, thanks to innovative technologies and cutting-edge techniques. Today, metal fabricators can access a wide array of specialized molds that cater to specific needs and requirements. From intricate shapes to custom designs, tooling molds have revolutionized the way metal fabrication is approached.

Benefits of Utilizing Tooling Molds

- Precision: Tooling molds enable manufacturers to achieve high levels of precision in their metal components, ensuring consistency and accuracy in each piece produced.

- Efficiency: By utilizing tooling molds, metal fabricators can streamline their production processes, reduce waste, and enhance overall efficiency in their operations.

- Customization: With custom-designed tooling molds, manufacturers have the flexibility to create unique and complex parts tailored to their specific requirements.

- Cost-Effectiveness: Investing in quality tooling molds can result in long-term cost savings by optimizing production and minimizing errors.

The Role of Tooling Molds in the Metal Fabrication Industry

Tooling molds play a pivotal role in the success of Metal Fabricators by offering a key solution to meet the demands of a competitive market. From speeding up production processes to ensuring top-notch quality in final products, these molds are indispensable tools that drive innovation and growth in the industry.

Embracing Innovation with Tooling Molds

As technology continues to evolve, metal fabricators are constantly exploring new ways to enhance their manufacturing capabilities. Tooling molds stand at the forefront of this innovation, providing a solid foundation for businesses to thrive and stay ahead of the curve in a rapidly changing landscape.

The Future of Tooling Molds

Looking ahead, the future of tooling molds in the metal fabrication industry holds endless possibilities. With ongoing advancements in materials, design techniques, and manufacturing processes, these molds are poised to drive unprecedented growth and innovation for businesses seeking to stay competitive and deliver excellence in their product offerings.

Discover the transformative power of tooling molds in the metal fabrication industry at deepmould.net